Technology

PSA - Pressure Swing Adsorption is a gas separation process which uses gas adsorption, (adherence to a solid surface) to separate the components of a gaseous mixture. PSA can separate numerous gasses. The most common application is Hydrogen purification.

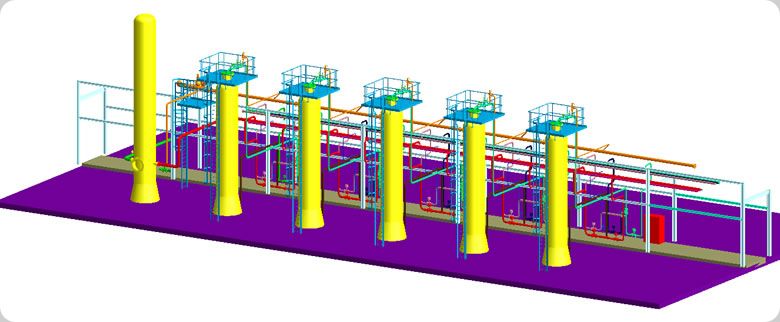

PSA usually consists of several adsorber vessels, skid mounted process valves and piping. Mostly, PLC control system drives PSA unit operation. PSA typically operates at ambient temperatures and at pressures up to 75 Barg. It processes mixture of feed gasses, which are selectively separated over different adsorbent materials, sensitive to specific gases. Thus PSA Product gas can reach purities as high as 99.99+ %.The impurities are adsorbed from the feed at the high pressure and desorbed as tail gas at low pressure. Surge tank typical for PSA unit is to dampen the Tail gas pressure and flow variations. Constant product and tail gas flow is a sign of properly operated PSA.

PSA is one of the three widely used gas separation processes. The other two being absorption and membrane permeation. Absorption is used for CO2, H2S, etc. removal. Membrane separation is used when product purity is not as critical and can be lower than 99.99+ %. When purity values around 95 ~ 98 % are sufficient, then Membrane purification is ideal solution.